The De-NOx system will help effectively remove nitrogen oxides generated in many industries, especially in the process of using fossil fuels (coal, oil, gas …).

DeNOx – NOx Reduction Technology comes in three variants: Selective Catalytic Reduction (SCR), Selective Non-Catalytic Reduction (SNCR) and Hybrid System (SCR+SNCR). The system can be selected basis the specific requirements of the customer and the suitability of the applications such as Coal Fired Boiler, Biomass Boiler, Coke Oven, Incinerators, Cement Kiln and all allied NOx generating processes.

The De-NOx system converts NOx into N2 and H2O by injecting reagent in the upstream of the flue gas, typically aqueous ammonia or urea. While SCR uses a catalyst to reduce NOx with high efficiency and low temperature (160 – 350˚C), SNCR is a technology that uses high temperature (900 – 1050˚C) to reduce NOx with equivalent efficiency. Our experts will analyze flue gas temperatures and related parameters to offer best solution to ensure lowest total cost of ownership and deliver optimum system output.

Thermax had set up a joint venture in 2010 with Babcock & Wilcox Power Generation Group (B&W) from the USA for manufacturing large boilers. B&W ‘s extensive experience, advanced technology and full-scope capabilities make our Selective Catalytic Reduction (SCR) systems the equipment of choice for reducing NOx by some of the cleanest and most efficient utilities and industrial facilities in operation.

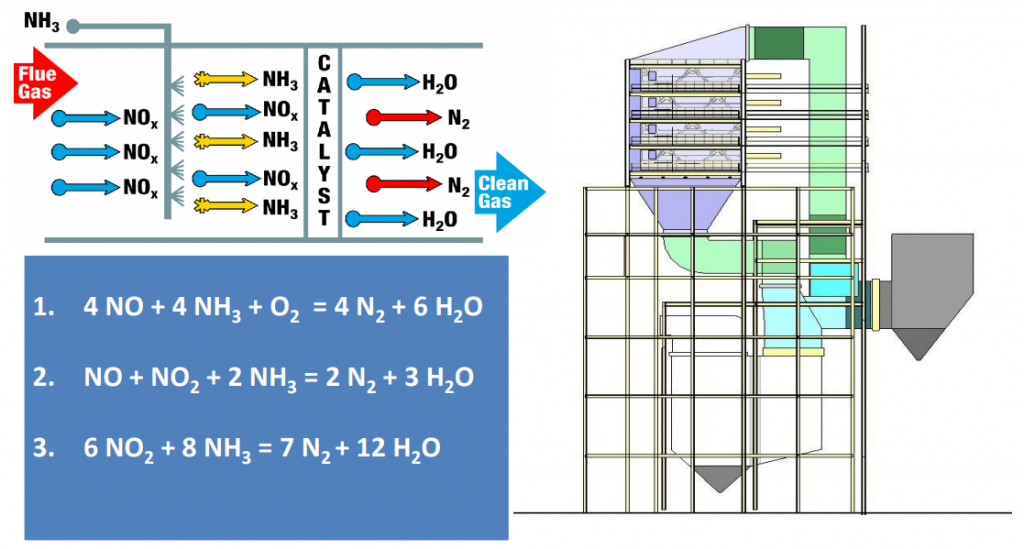

Principle of SCR Process

SCR systems catalytically reduce flue gas NOx to N2 and H2O. This technology is the most effective method of reducing NOx emissions especially where high removal efficiencies (70 to 95%) are required. The NOx reduction takes place as the flue gas passes through a catalyst chamber. Before entering the catalyst, ammonia is injected into the flue gas where it is mixed.

Typical Coal Fired SCR System

- Catalyst

- Ammonia injection grid (AIG)

- Static mixers

- Flow distribution devices

- Flow straightener

- Catalyst cleaning equipment

- Catalyst loading equipment

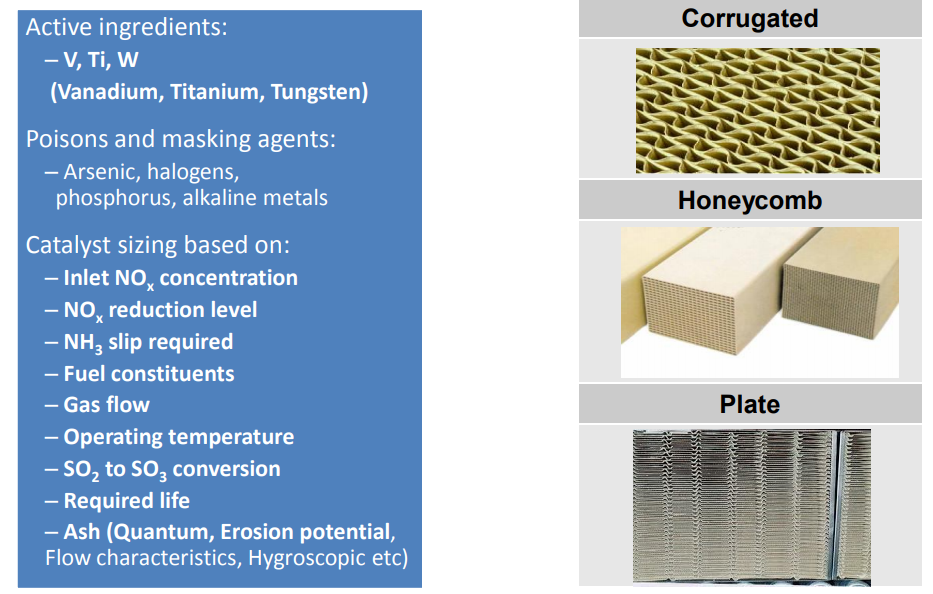

Catalyst

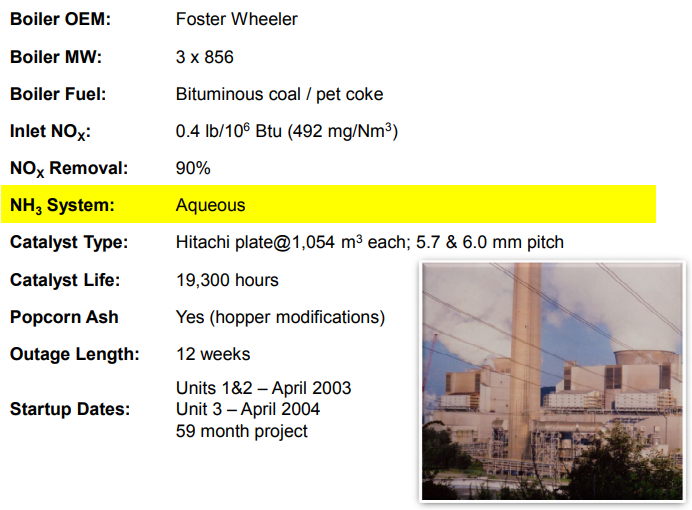

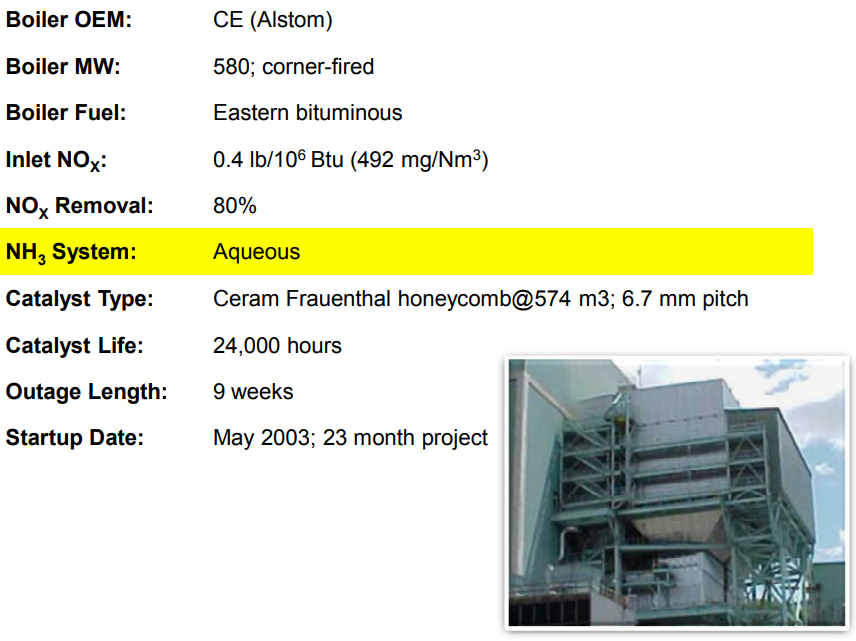

Typical projects

Leave a comment