HISTORY

Established in 1951 – 67 Years old Engineering Group

- Most Modern Gear Manufacturing Plant having entire Range of Power Transmission Equipment’s.

- One of the 1st to introduce the concept of Mechanized Bulk Material Handling Equipment’s.

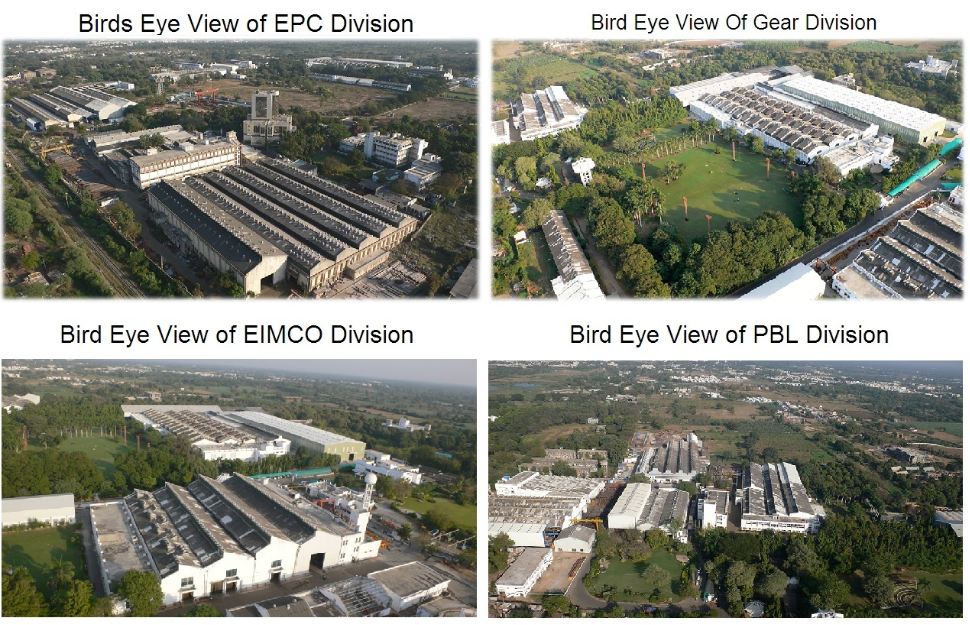

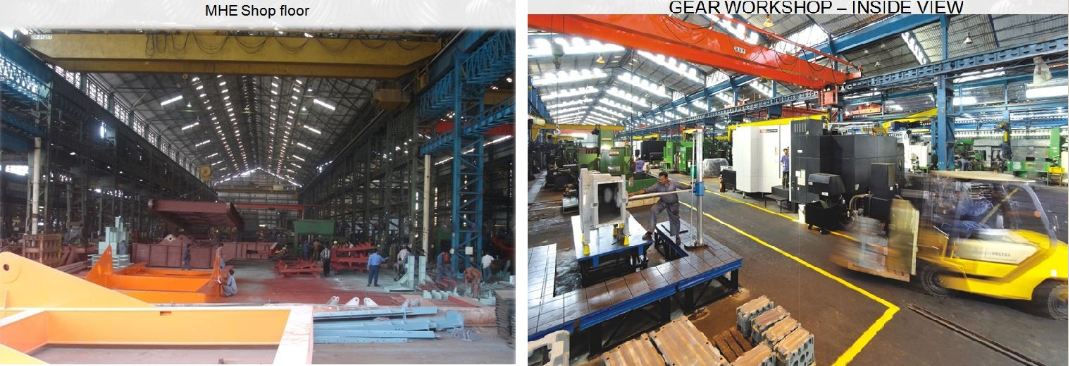

- Total land Area 631,540 Sq. Mtr.

- Total Construction Area 190,000 Sq. Mtr.

- More than 750 Nos. of Machine Tools.

- Entire Range of Industrial Geared Motors & Reducers.

- Underground Mining Equipments.

- In house Foundry & Fabrication Facility.

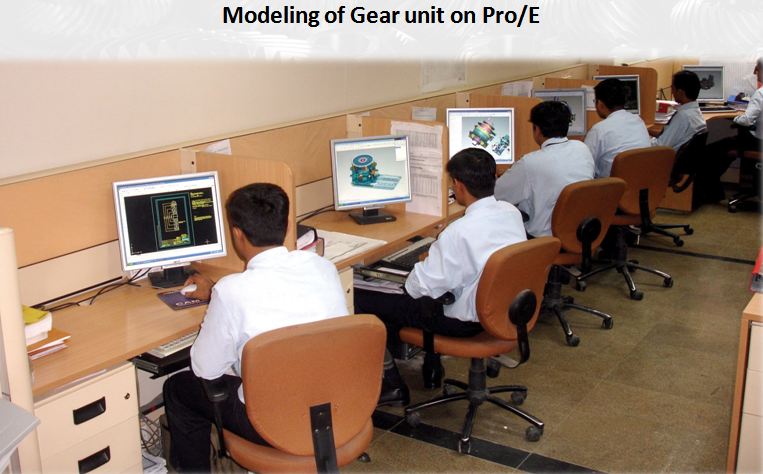

- Own Information Technology Centers.

- Manufacturing plants at UK, Sweden, Thailand, USA & Netherland other then India.

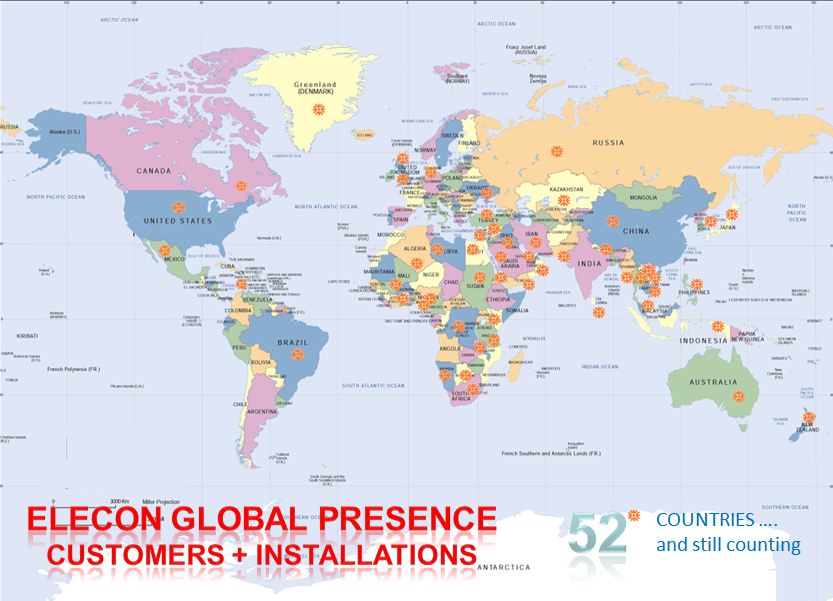

As a multinational corporation, ELECON’s products are available worldwide.

OPERATION SECTORS

1. EPC DIVISION

- Elecon EPC Projects Ltd. is a wholly owned subsidiary of Elecon Engineering Company Limited.

- Undertaking EPC projects of Bulk Material Handling Systems for materials like Coal, Lignite, Iron Ore etc.

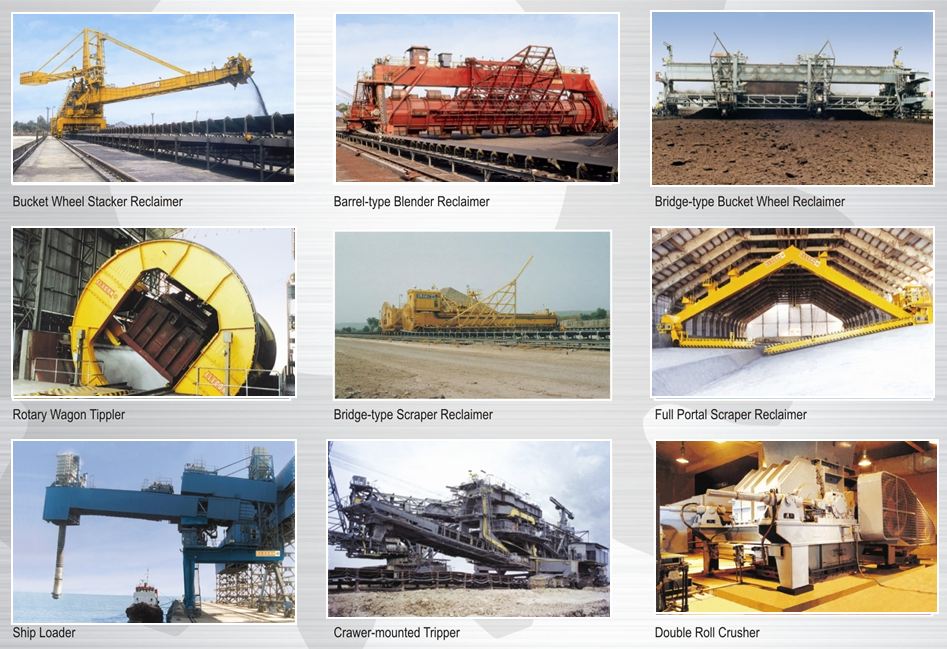

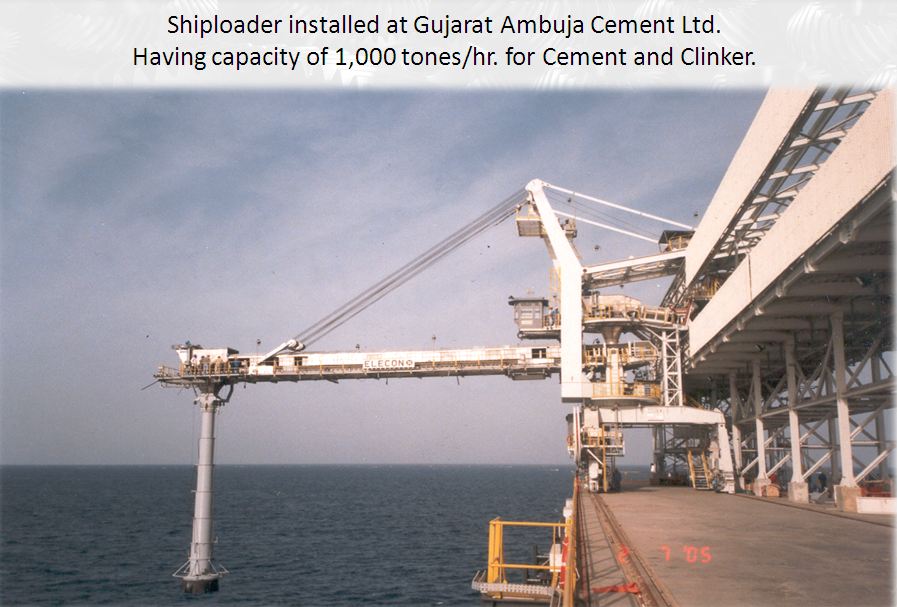

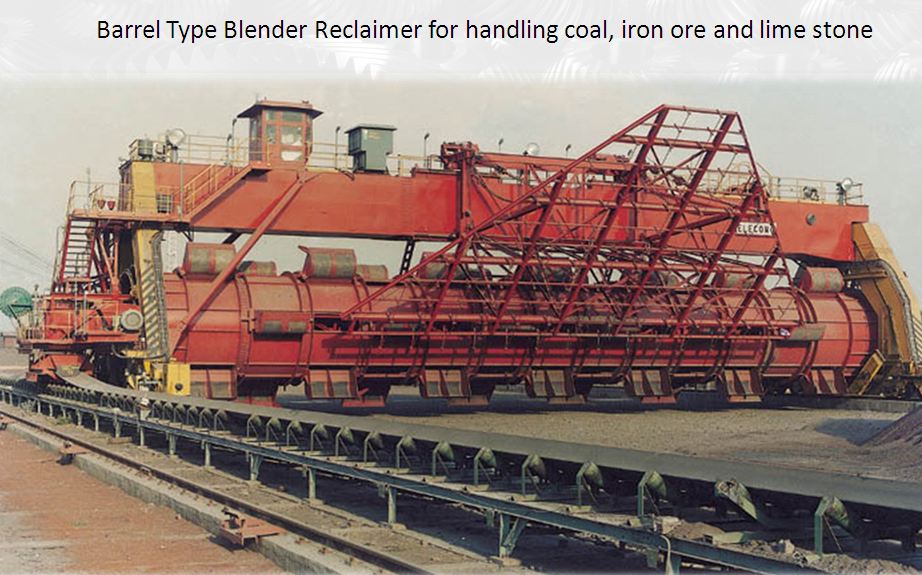

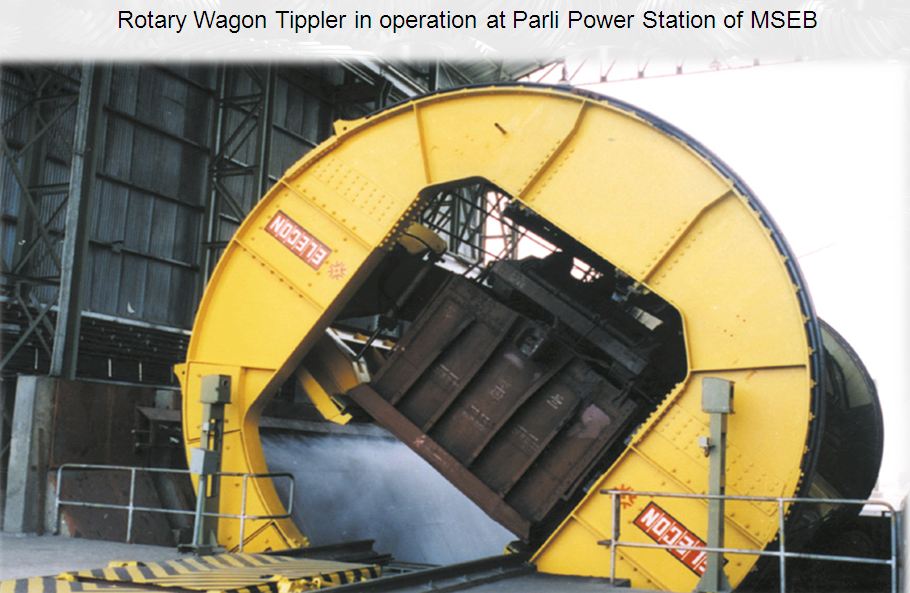

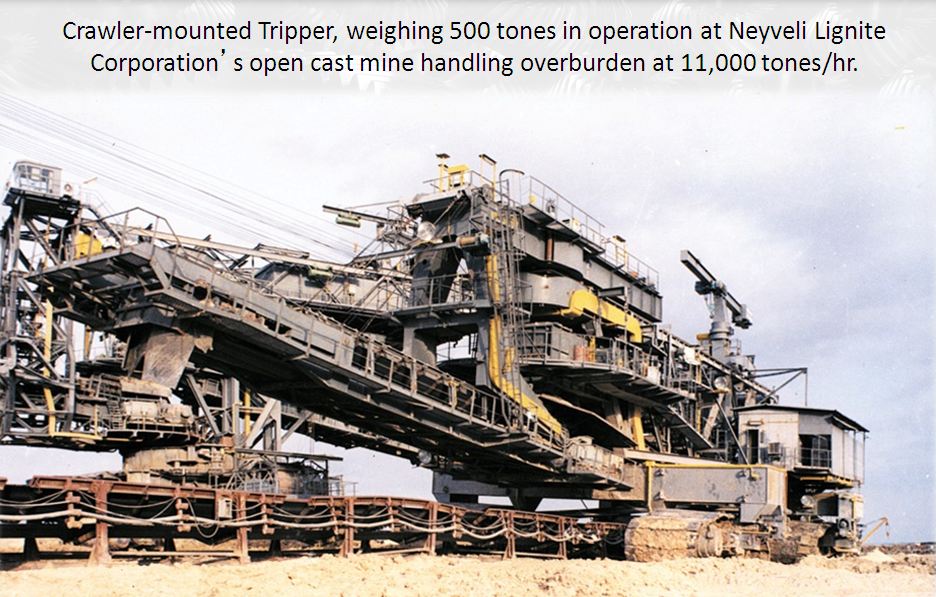

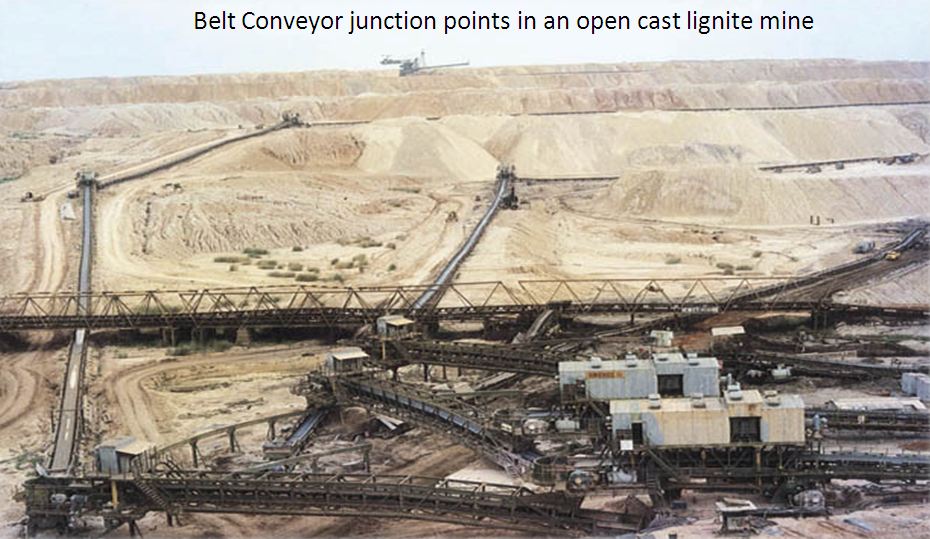

- Major manufacturing equipment includes:-Wagon Tipplers, Stackers & Reclaimers, Wagon Loaders and Ship Loaders, Crushers, Feeders and Screens, Idlers & Pulleys, Conveyors an Pip Conveyors, Magnetic Separators, Belt Weighers and Bagging Machines.

- Spread over an area of about 172, 000 Sq. Mtr., Elecon EPC is equipped with latest CNCs and other machines like Robot Arm Welding Machine, Horizontal Boring Machine, Vertical Machining Centers, Floor type Boring Machines with Turning Tables.

EPC Products

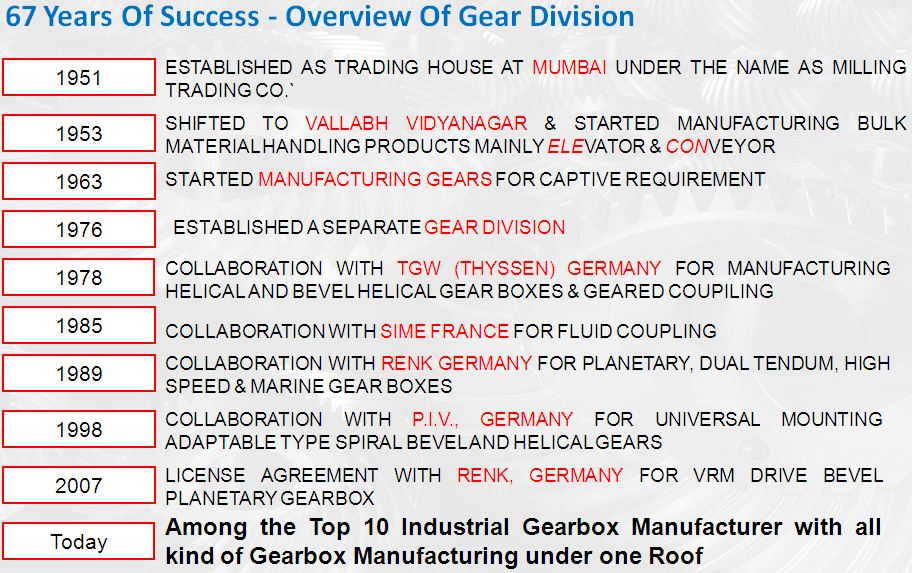

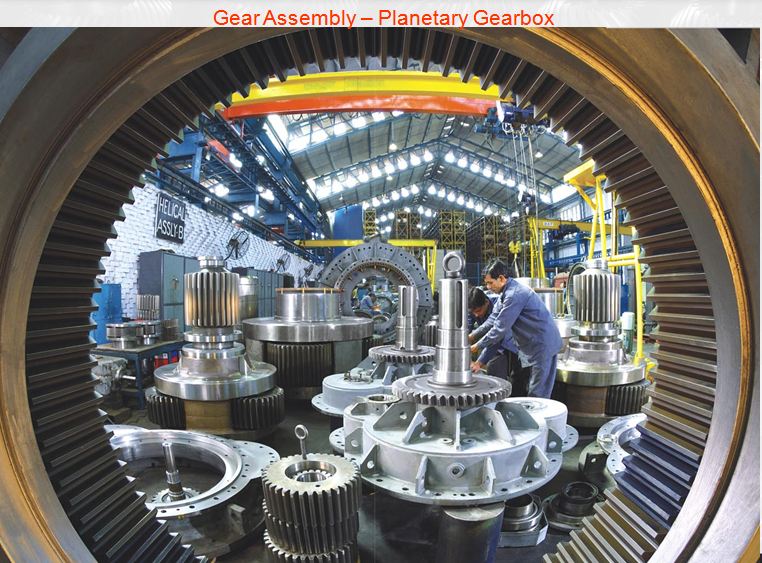

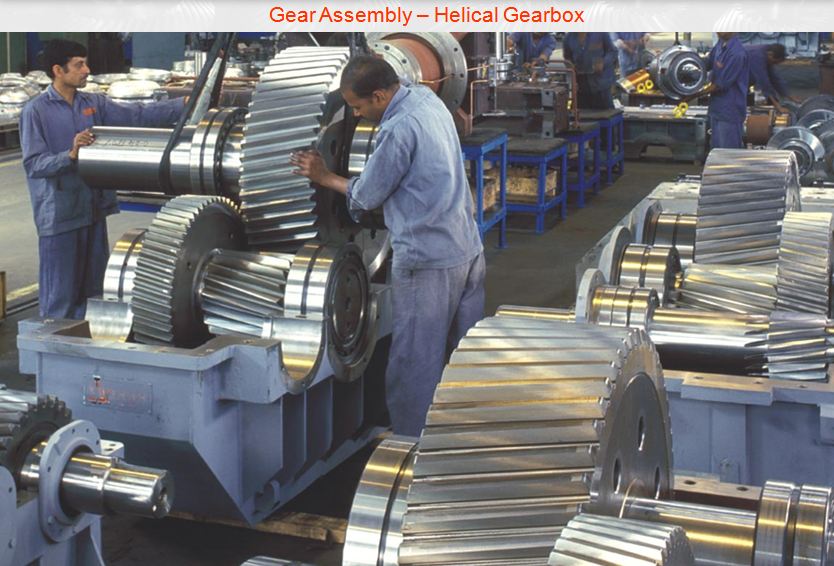

2. GEAR DIVISION

Elecon Engineering Co. Ltd.

- Started Gear Manufacturing in 1963.

- In 1976 Established separate Gear Manufacturing Plant.

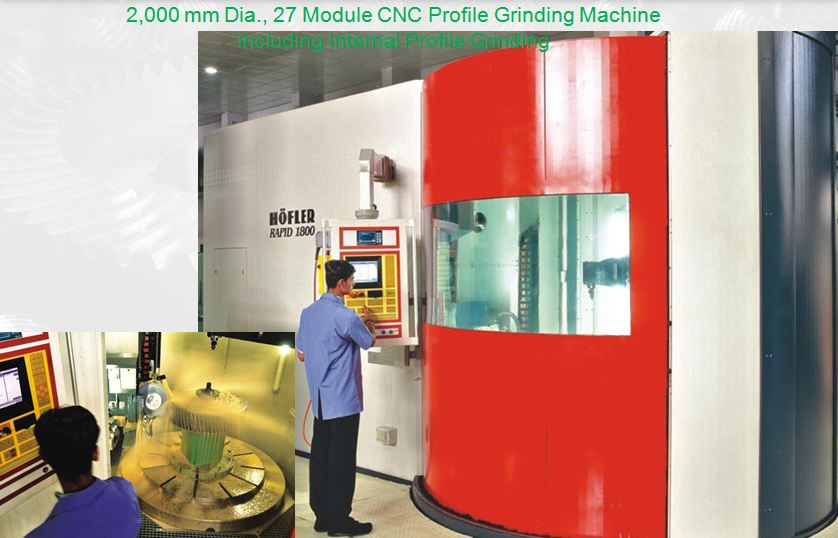

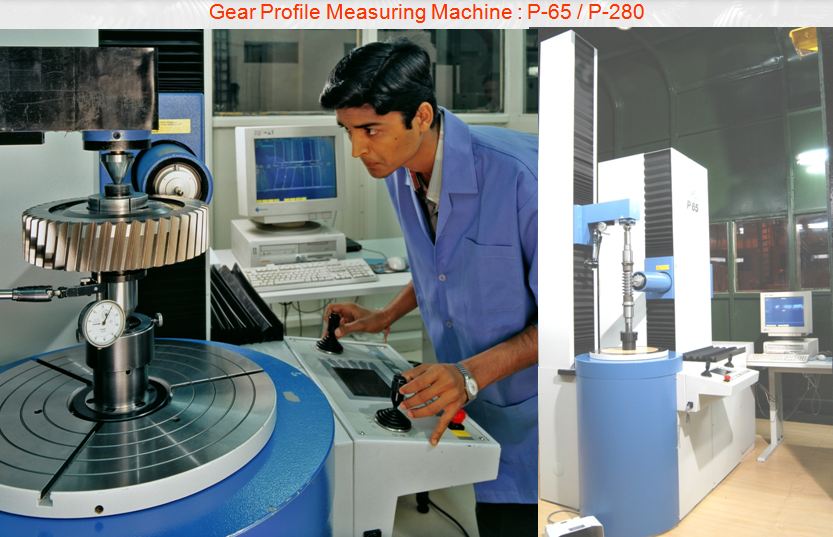

- 1st to introduce modular design concept, case hardened and ground gear technology in India.

- Largest Gear Manufacturing facility in India & Thailand.

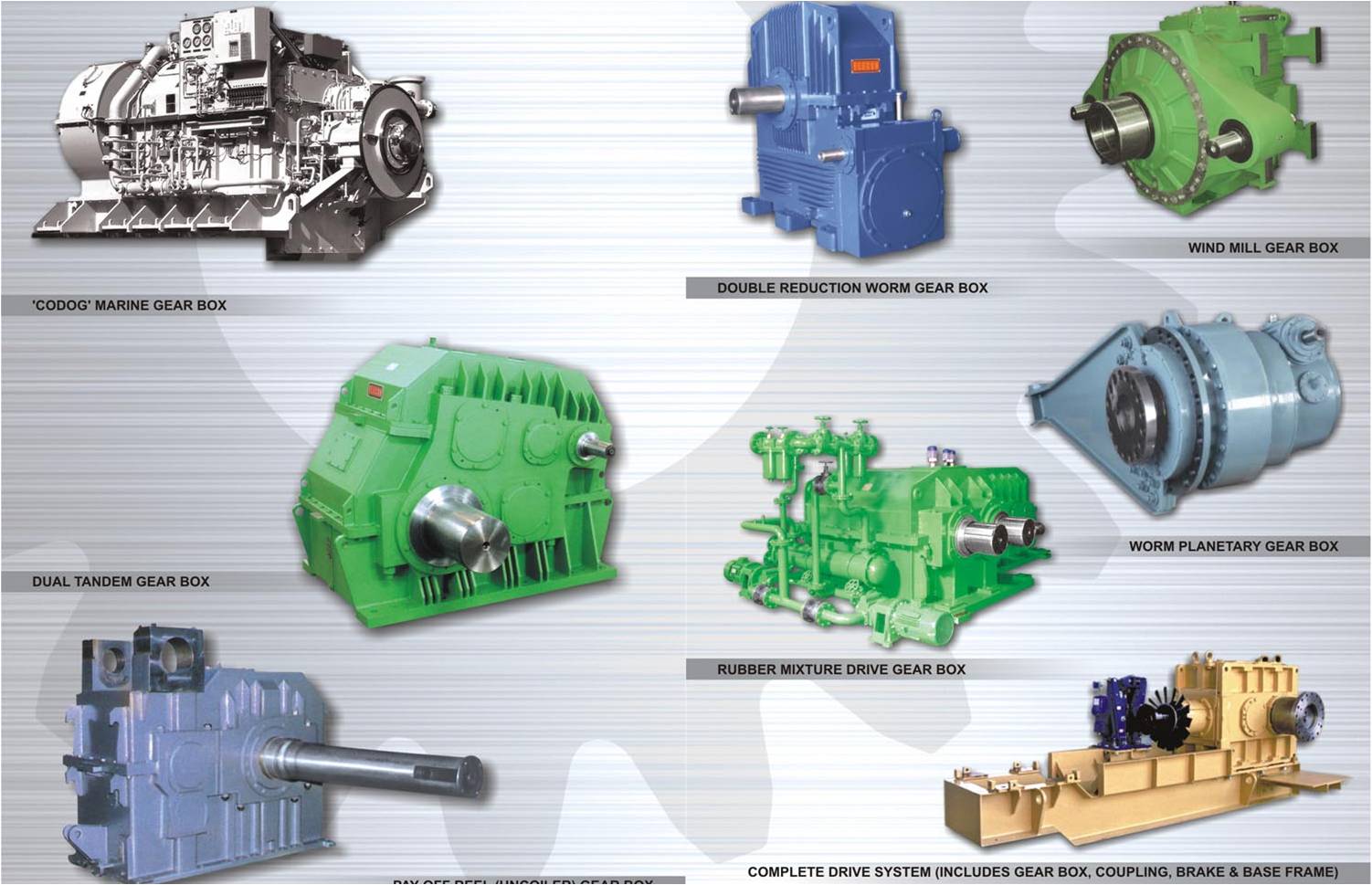

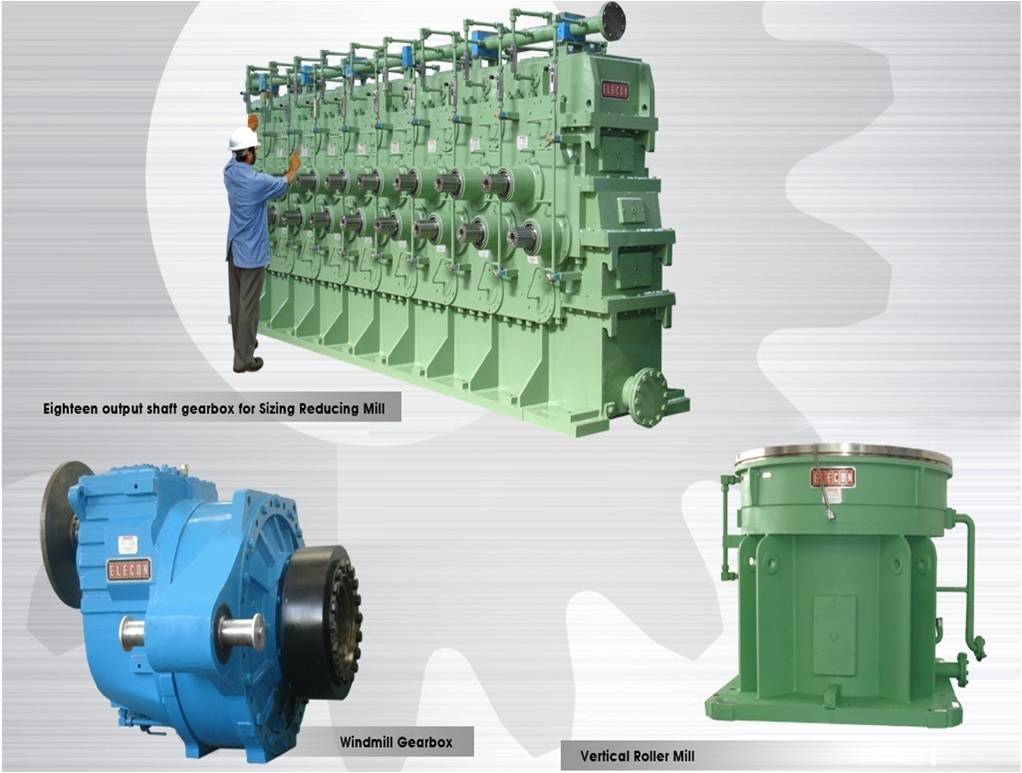

- Wide Product range includes Helical, Bevel Helical, Planetary, High Speed, Custom Built Gear boxes and Couplings.

Bhanubhai Memorial Centre Of Excellence – BMCE

The Bhanubhai Memorial Center of Excellence (BMCE) is a testament to the commitment of Elecon to always remain a step ahead in technology.

With a total investment of over Euro 15 Mi., Elecon has spared no expense in preparing to reach the next level in gear manufacturing.

Gear Product Range

3. ALTERNATIVE ENERGY DIVISION

Elecon manufactures Wind Turbines in 60 and 50 hz frequencies with globally recognised technologies.

SALIENT FEATURES

- Elecon Turbowinds T600-48DS is designed to suit Class II wind & any climatic conditions. The T600-48DS is simple and robust turbine, which is easy for operation with minimum downtime. All its components , tested for longer designed life under adverse conditions, make this Turbine popular.

- Elecon T600-48DS Turbine designed with Dual Speed Generator, allows the Turbine to perform better even in Low Wind Speeds. T600-48DS uses 3 stage Gear Box, designed and manufactured by ELECON itself, gives better reliability to its stakeholders in long term.

- Elecon T600-48DS uses aerodynamically designed rotor blades manufactured by world renowned supplier. Its Active Pitch Controls are hydraulically operated and harness optimum wind all the time.

- Its unique safety features like – failsafe blade feathering in the event of grid loss, prevent damage to the drive train.

- It is also provided with independent over – speed trips, which activate the backup safety system (disc brake) in case of any eventuality.

- The sturdy design of its Tubular Tower provides vibration free structure to the Turbine to handle any dynamic/static loads in abnormal wind conditions. Enclosed Tower and Nacelle allows safe and comfortable maintenance under any weather conditions.

- Specially designed microprocessor based Control System of Elecon T600-48DS produces harmonics free grid friendly power. Its ability to work in all conditions makes it a versatile Turbine all over the world.

PROJECT

- NARANSARI WINDFARM

- VARVALA WINDFARM

4. FABRICATION & FOUNDRY DIVISION

FABRICATION SHOP

Capacity :

- 200 MT Fabrication per Month.

- Single Component of 20 MT Weight.

- Fabrication of Heavy Machine Components.

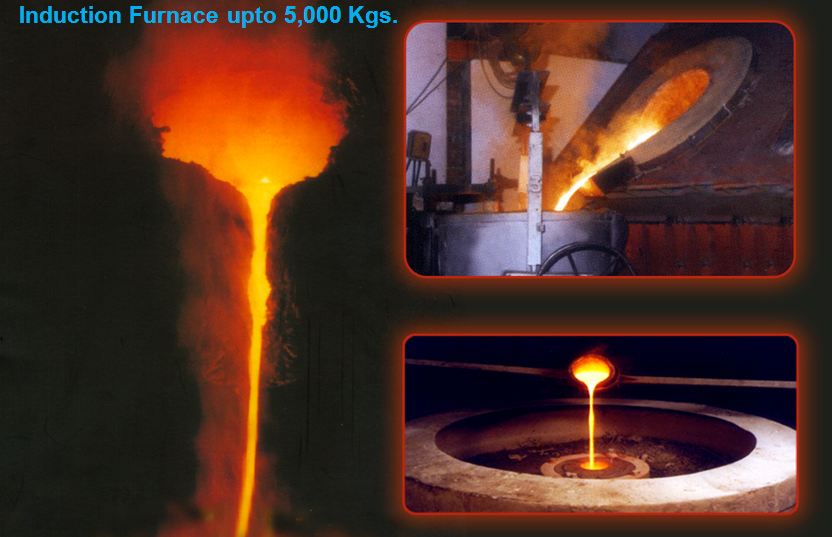

FOUNDRY

Products :

- Ferrous : Steel and Alloy Steel Castings.

- Non Ferrous : Copper base and Aluminum base Alloy castings.

Users :

- Cement, Sugar and Valve Industries.

- OEMs for Earth Moving & Material Handling Equipment.

- OEM for Crushing Equipment’s.

- General Engineering.

Foundry Products

5. SMALL GEAR DIVISION – PBL

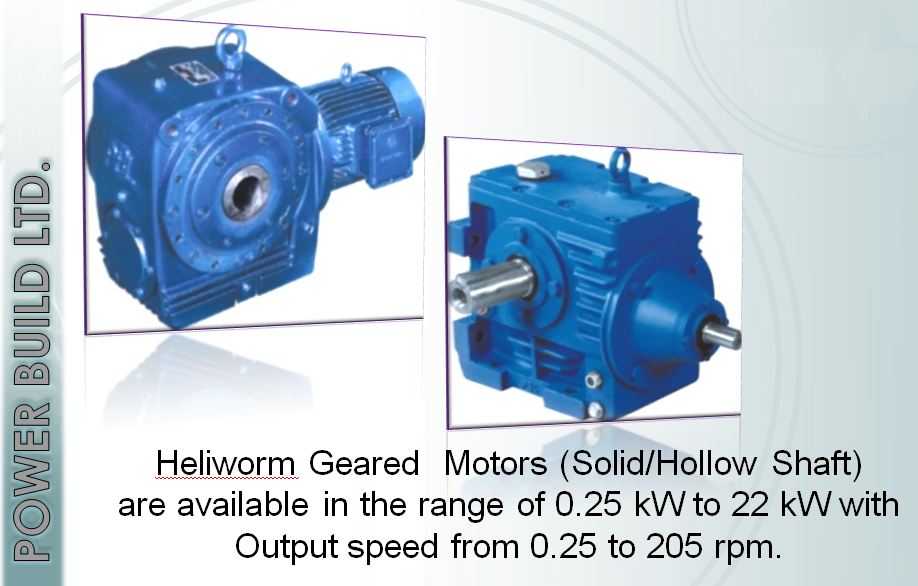

POWER BUILD PVT LTD are the leading providers of high quality, standard, modified standard and custom engineered geared motors.

Geared motors and gearboxes are the heart of any engineering product. It is not just the torque and speed but the RELIABILITY of the Geared Motor that defines the performance of your product or equipment. So, whenever you think of Geared Motors, choose Reliability over the ordinary.Choose RADICON POWERBUILD, a name that personifies RELIABILITY and VALUE.

Experience the power of proven Performance and the advantage of RADICON POWERBUILD.

Product Range

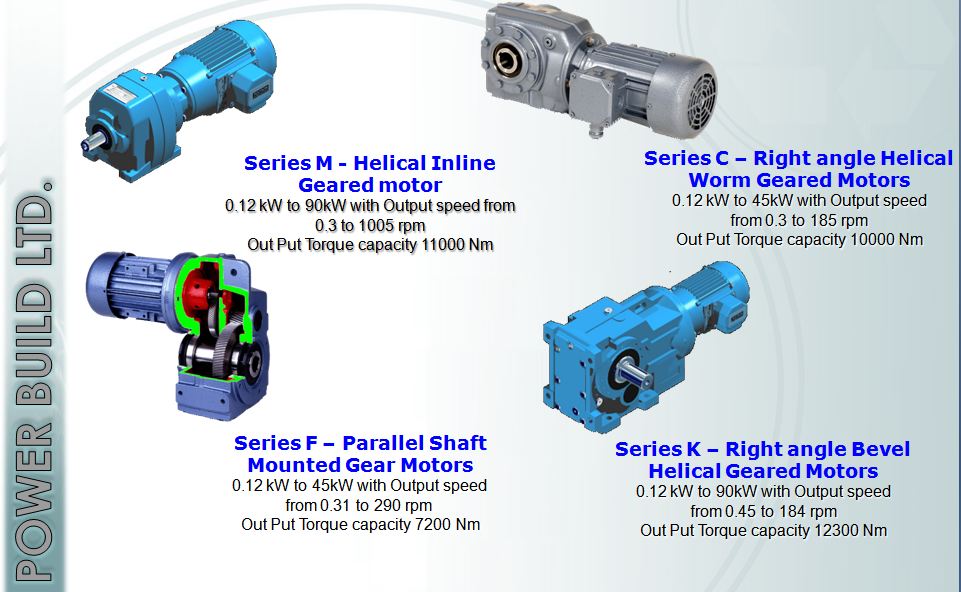

Introduction of New M,C,F & K- Series

PBL introduces new generation, very efficient and compact drive solution in the form of M, C, F and K series geared motors and reducer, assembled from a family of modular kits, maximizing availability.

Small Planetary Gearbox – With or Without Motor

Out Put Torque capacity upto 25,000 Nm

6. VEHICLE DIVISION – EIMCO ELECON

Eimco Elecon is a leading and established manufacturer and supplier of various Mining and Construction Equipment in India with operations supported by network of Sales and Service establishments located at various strategic locations throughout the country. It was incorporated in 1974 and went public in 1992. Situated at Vallabh Vidyanagar, Anand, Gujarat, Eimco Elecon is spread over a stretch of 15 acres.

Product Range

MANUFACTURING CAPACITY

Infrastructure

Machine & Technology

Leave a comment