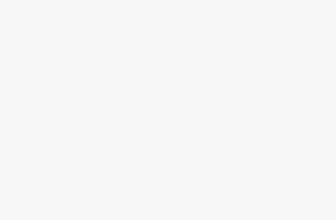

- WFGD: Wet Flue Gas Desulphurisation, is a proven and efficient design that uses an open spray tower and high-velocity mist eliminators. Thermax-MET limestone/gypsum technology delivers SO2 removal efficiencies of 98+%, and demonstrates excellent performance results and favorable capital, operating, and maintenance factors compared to other designs. Our design is a global standard of excellence and has a proven reputation for its efficiency, reliability, and flexibility in addressing the most difficult requirements

- DSI: Dry Sorbent Injection

- SDA: Spray Dryer Absorber (SDA) technology is a lime-based semi-dry FGD method that is coupled with a fabric filter or electrostatic precipitator, making it a true multi-pollutant control solution. The SDA technology is a proven and successful design installed on a variety of global flue gas treatment applications including lignite, PRB, sub-bituminous coal, coal/wood-fired boilers, and waste-to-energy (WTEMSW) plants. SDA installations have consistently achieved sulfur dioxide (SO2), hydrochloric acid (HCl), and particulate matter (PM) emission limits in accordance with customer specifications.

Product Features

- Wet FGD system is equipped with ALRD® Technology for achieving higher SO2 removal efficiency with lesser power consumption

- SDA uses specially designed atomizers to form fine droplets of reagents for a better reaction

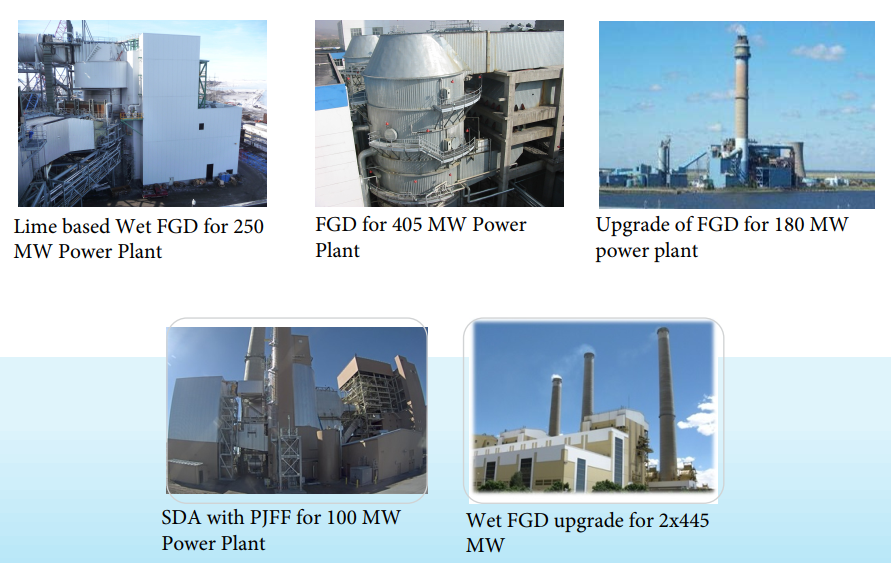

- Two loop control concept in semi-dry system ensures efficient operation and better control

- Cost-effective technology for SO2 removal efficiency of 98+%

- Minimum disposal cost with saleable gypsum Byproduct

- Oxidized mercury control co-benefit